Stainless Steel

- Home

- Stainless Steel

Stainless Steel Pipe suppliers, Stainless Steel Pipe Fittings, Stainless Steel Pipe

Fittings manufacturers in India, Stainless Steel Flanges suppliers

STAINLESS STEEL: - Conforming to Gr. 201, 202, 301, 303, 304, 304L,

316, 316L, 316 TI 309, 310, 317 , 321 , 347 , 409, 410 , 416 , 420 , 430 , 440 ,

904L ETC

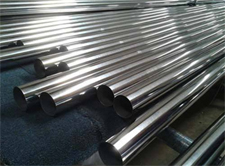

SHAPES :- SEAMLESS PIPES / ERW PIPES / PIPES FITTINGS / FORGE

FITTINGS / FERRULE FITTINGS / DAIRY FITTINGS / FASTNERS / ANCHORS / TUBES / ROUND

BARS / HEX BARS / SQUARE BARS / FLAT / SHEETS - PLATES / COILS / ANGLES / CHANNELS /

FLANGES / VALVES ETC

FINISHES :- 2B, 2D, HR, CR, BA (Mirror Finish) No.8, Satin, Met

with Plastic Coated.

.png)

What is Stainless Steel 304/304L?

304 Stainless is a low carbon (0.08% max) version of basic 18-8 also known as 302. Type 302 has 18% chromium and 8% nickel. Type 304 has slightly lower strength than 302 due to its lower carbon content. Type 304 finds extensive use in welding applications because the low carbon permits some exposure in the carbide precipitation range of 800°F - 1500°F without the need for post-annealing operations. However, the severity of corrosive environments may necessitate annealing after welding or the use of 304L.

Type 304L has a carbon content of 0.03% or less. This alloy can be used in the as-welded condition without becoming susceptible to intergranular corrosion. Stainless Steel Grade 304 is the standard "18/8" stainless; it is the most versatile and most widely used stainless steel, available in a wider range of products, forms and finishes than any other. It has excellent forming and welding characteristics. The balanced austenitic structure of Grade 304 enables it to be severely deep drawn without intermediate annealing, which has made this grade dominant in the manufacture of drawn stainless parts such as sinks, hollow-ware and saucepans. For these applications it is common to use special "304DDQ" (Deep Drawing Quality) variants. Grade 304 is readily brake or roll formed into a variety of components for applications in the industrial, architectural, and transportation fields. Grade 304 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

Grade 304L, the low carbon version of 304, does not require post-weld annealing and so is extensively used in heavy gauge components (over about 6mm). Grade 304H with its higher carbon content finds application at elevated temperatures. The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures.

Key Properties

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM A240/A240M. Similar but not necessarily identical properties are specified for other products such as pipe and bar in their respective specifications.

Specifications - Stainless Steel 304/304L

A249, A403, A182, A351

SA269, SA249,SA403, SA182, SA351

Chemical Composition - Stainless Steel 304/304L

Design Features - Stainless Steel 304/304L

Typical Applications - Stainless Steel 304/304L

Tensile Requirements - Stainless Steel 304/304L

Tensile Strength (KSI): 70

Yield Strength (KSI): 25

KSI can be converted to MPA (Megapascals) by multiplying by 6.895.

Most useful fittings in Stainless steel 304/304L (Butt-weld Stainless Steel Pipe Fittings)

High Pressure Forged Stainless Steel Pipe Fittings